Lignum Scan X01 – Redefining Wood Quality Inspection

(under development)

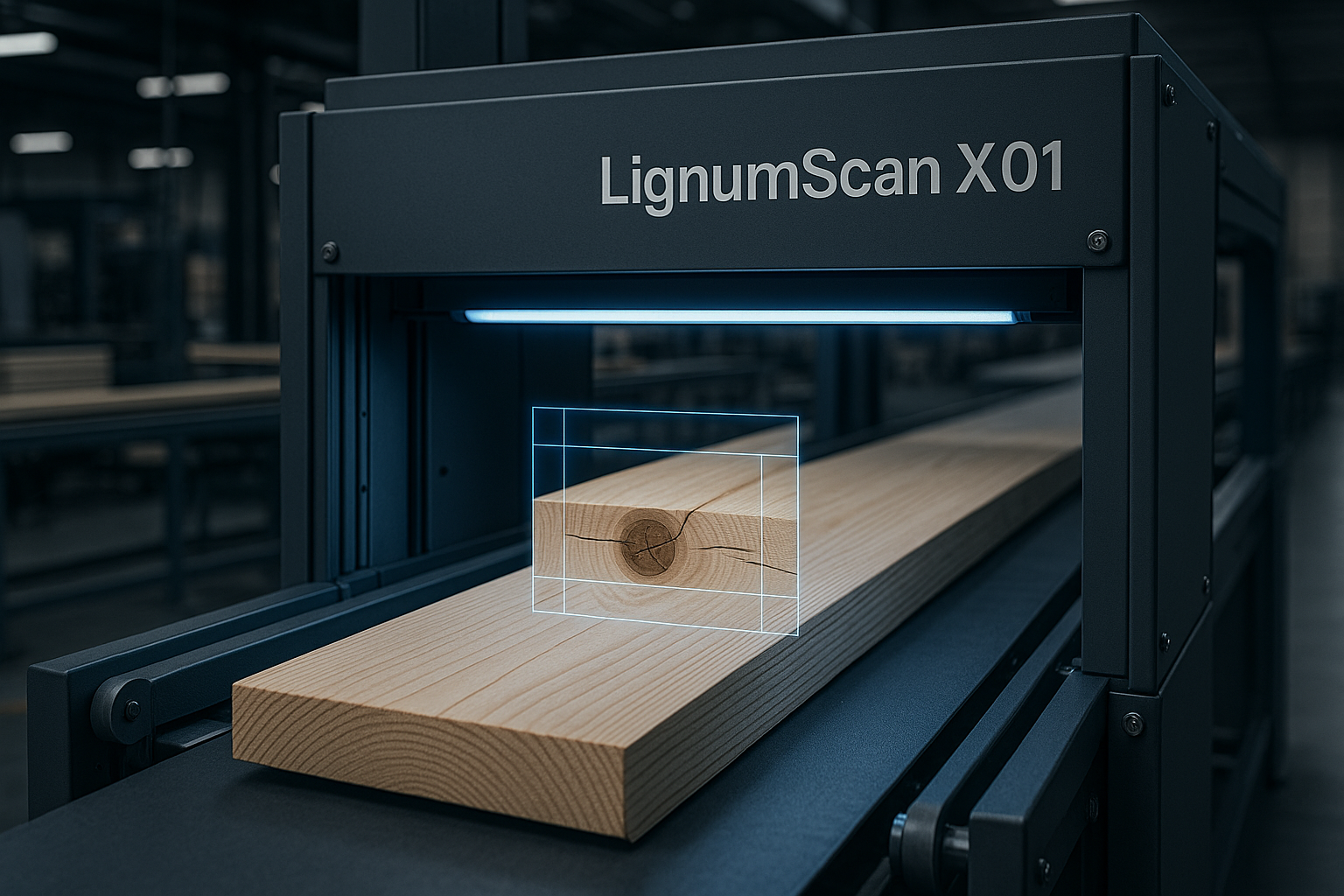

Meet the LignumScan X01 – Redefining Wood Quality Inspection

In the world of industrial wood processing, precision, consistency, and seamless data flow are everything. The Lignum Scan X01 by Lignum Vision is engineered to the highest standards of automated wood inspection, delivering instant detection of knots, cracks, discoloration, and other structural defects — without slowing down your line.

Driven by advanced imaging and AI-powered software, the Lignum Scan X01 integrates effortlessly into your production workflow, giving you complete control over quality, yield, and traceability.

Engineered for Accuracy

At its core sits a best-in-class optical detection system, combining:

- High-resolution line-scan cameras

- Multi-angle LED illumination

- AI-based defect recognition algorithms

→ Micrometer-level precision, every time.

Built for Performance

- Real-time scanning of knots, splits, grain disruptions, resin pockets and more

- High throughput (up to 100 m/min1) to keep pace with your fastest lines

- Robust industrial design with self-calibrating optics for minimal upkeep

- Cloud-ready analytics to track trends, batches and performance KPIs

Connectivity & Integration

LignumScan X01 talks your language. Our standard communication protocols ensure rock-solid, low-latency data exchange with any modern control system:

- OPC UA for secure, platform-agnostic data modeling

- TCP/IP for straightforward networked connectivity

- PROFINET for real-time deterministic I/O in Siemens and Rockwell environments

Plug into your PLC, SCADA or MES and start feeding quality data straight into your dashboards.

Smart Investment, Fast ROI

Cut waste, boost yield and guarantee top-tier product quality. With the LignumScan X01 you’re not only streamlining production—you’re future-proofing your plant.

Whether you’re automating manual inspection, scaling up capacity or breaking into premium quality markets, LignumScan gives you the competitive edge to stay ahead.

Experience the next generation of wood defect detection.

Contact us today.

¹ Actual throughput depends on board size, line speed and lighting configuration; please consult our engineering team for exact figures.

Learn more about us.